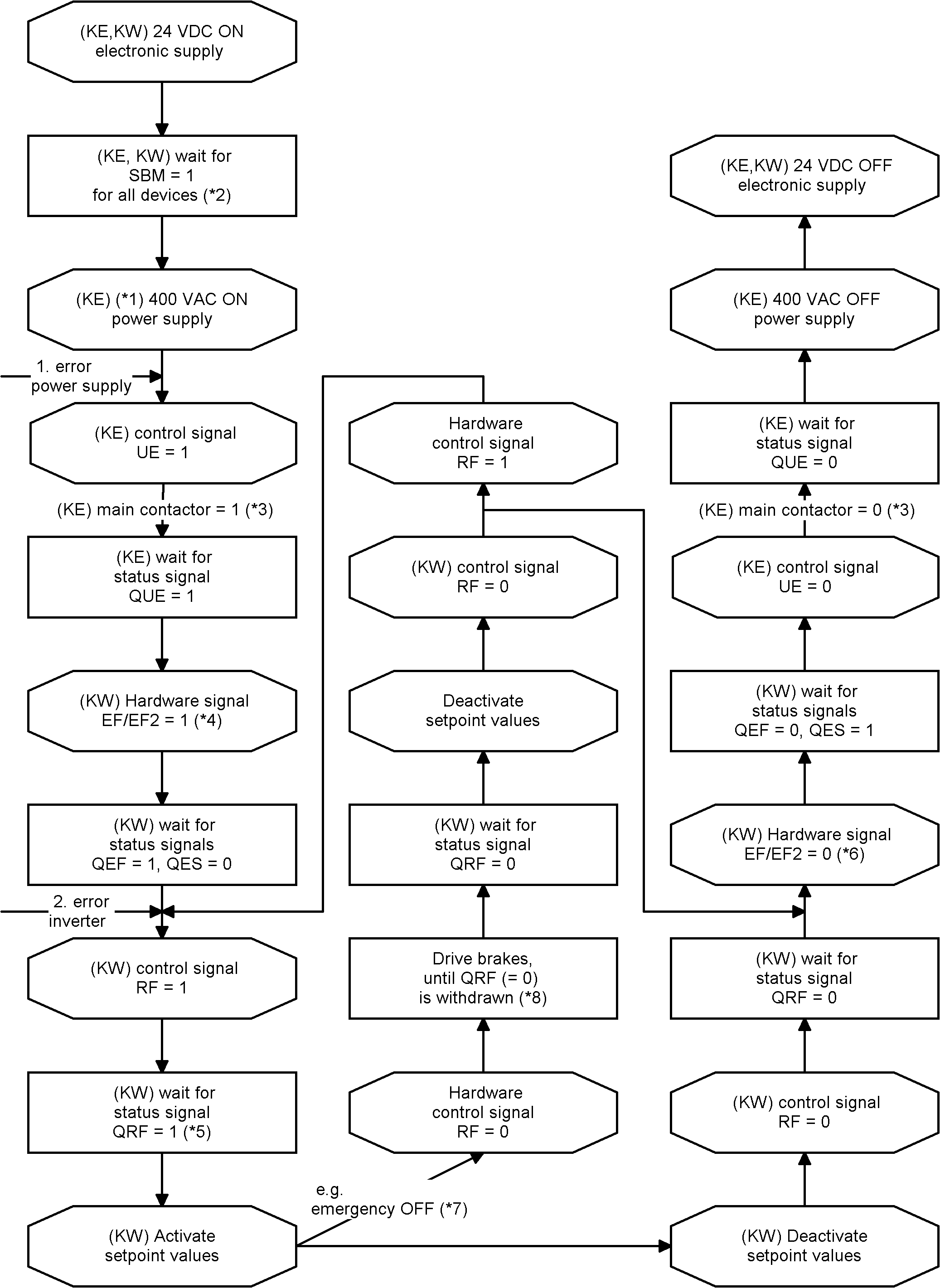

Switch-on and -off flow chart

|

*1 |

Close emergency OFF circuit (if existent). |

| *2 |

The module specific 'System ready' messages (SBM = 1) from the KE and KW modules signal the error-free states. |

| *3 |

If present, the required external main contactor is actuated by the KE. The delay time until the contactor is actuated via terminal X20 (EH1/EH2) depends on the DC bus capacities connected to the KE. |

| *4 |

Only devices with EF logic: Hardware signal EF/EF2 must be applied at the latest at that time. |

| *5 |

Delay time until QRF is set depends on the connected motor resp. whether the data set must be newly calculated because of a modification of drive specific parameters. |

| *6 |

Only devices with EF logic: Reset hardware signal EF/EF2 if the motor has to be in a safe torque-free state afterwards. |

|

*7 |

RF will be disabled via BE. BE is linked with PLC signal, see ID32796 'Source RF'. |

|

*8 |

Motor is braked to a standstill after the ramp ID32782 'Deceleration ramp RF inactive'. |

| *9 | Pulse ≥ 1 ms. |

| *10 |

Each inverter generated a DC bus error. |

Explanation of the status and control signals: Siehe 'Status and control signals'.

|

|

KW-R07 / -R17 For the machine startup of a controller card with functional safety, the safety functions must be de-activated. Therefore, the safe inputs must be connected stringently, and the SafePMT parameter set must be adapted. Without these adaptations, the startup of a servo motor is not possible. See document 'Safety manual; functional safety' (Part no. 203446), chapter 'Running KW-R07 / -R17 |