Encoder plug M23 - Siemens compliant

|

NOTICE |

|

|---|---|

| Material Damage! |

Material damage when plugging in the The plug must be aligned before insertion into the socket. The pin contacts are engaged before the codings of the plug and socket interlock. The pin contacts will be bent if the plug is turned when being inserted and the pin contacts are already engaged or if the plug and socket are not properly aligned and the screwcap is tightened. Steps to prevent:

|

|

NOTICE |

|

|---|---|

| Material Damage! |

Damage to the rotatable right-angle connector! The angular connector can be rotated and aligned as desired with the plugged-in and screw-tightened mating connector (approx. 16 locking positions). For alignment, a torque of approx. >8 Nm is required. The alignment makes variable mounting positions and an adaptable motor connection possible. If the connector is frequently re-aligned, or aligned without a mating connector, by means of pliers or other tools, the thread of the screwcap can be destroyed and the sealing surface damaged. Steps to prevent:

|

|

|

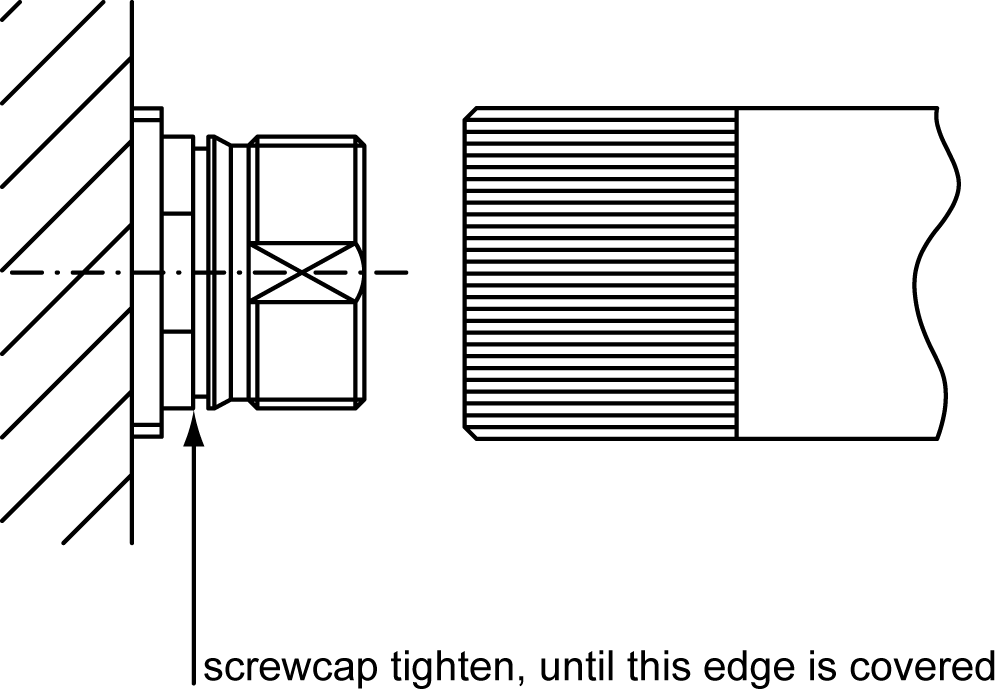

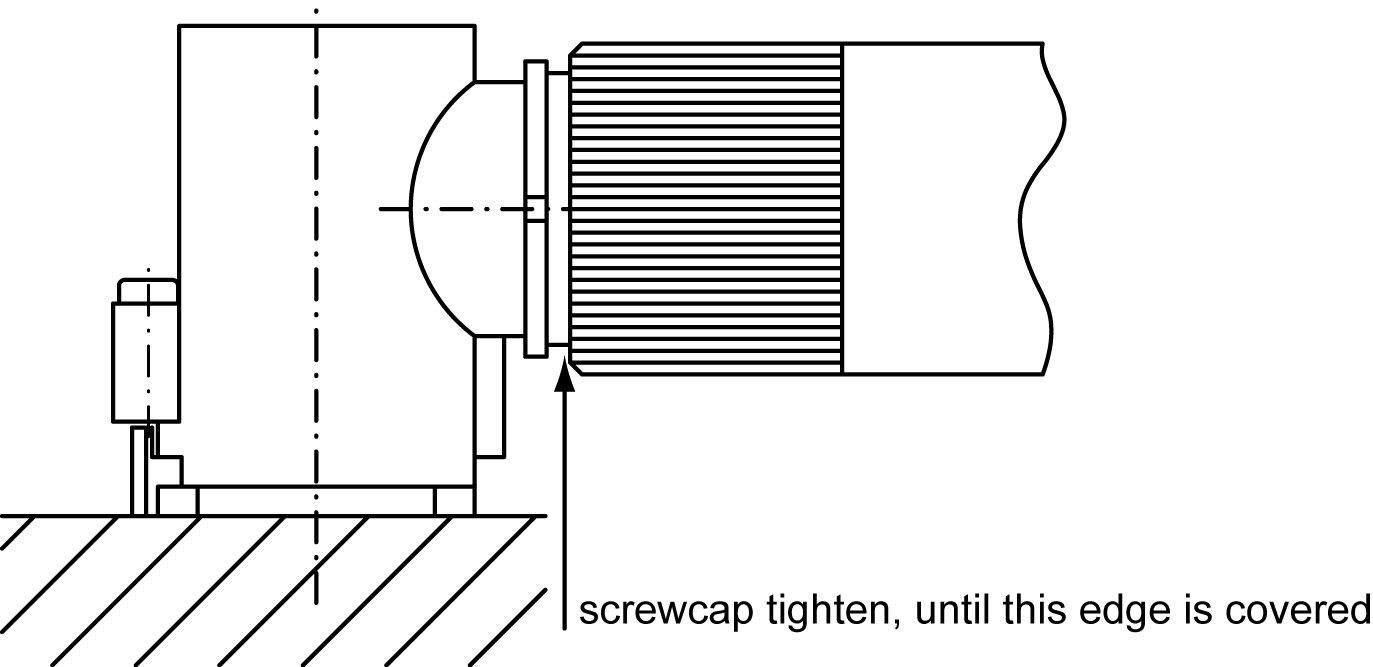

The screwcap has to be plugged in and screwed on up to the mark, else the pins do not make contact and encoder errors can occur.

Picture name: ZCH_DYNASYN_Stecker_gerade

Picture name: ZCH_DYNASYN_Stecker_gewinkelt |

Description:

The encoder plug at the motor is connected to the encoder input on the converter by means of the encoder cable. If necessary, equip the connection cable with twist, strain and shear relief, as well as kink protection. Forces that act on the connector permanently are not permissible!

Technical data:

The maximum permitted length of the cable is specified by the converter connection.

Design:

|

Type |

Pins |

Class |

|---|---|---|

|

Encoder plug M23, metal |

17 |

Built-in box with male contacts |

Assignment:

|

Drawing |

Connection |

Signals |

Description |

|---|---|---|---|

|

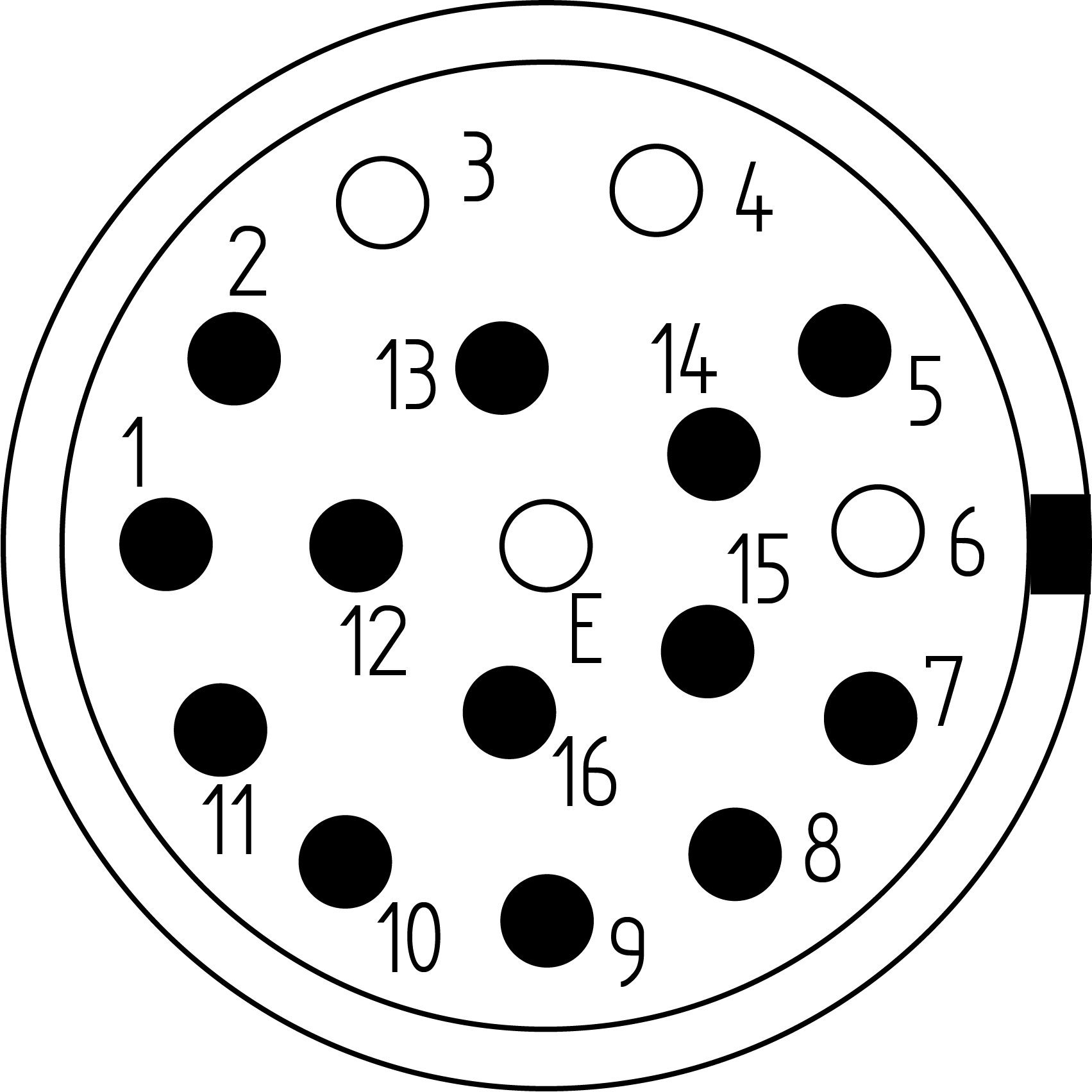

Front view of the device side

|

1 |

G1N (+COS) |

Analogue track 1 not inverted |

|

2 |

G1I (-COS) |

Analogue track 1 inverted |

|

|

3 |

DAT+ |

Encoder specific signal |

|

|

4 |

- |

- |

|

|

5 |

CLK+ |

Encoder specific signal |

|

|

6 |

- |

- |

|

|

7 |

GND |

Reference for the supply |

|

|

8 |

TH+ |

Temperature sensor motor winding + |

|

|

9 |

TH- |

Temperature sensor motor winding - |

|

|

10 |

5P |

Supply VDC |

|

|

11 |

G2N (+SIN) |

Analogue track 2 not inverted |

|

|

12 |

G2I (-SIN) |

Analogue track 2 inverted |

|

|

13 |

DAT- |

Encoder specific signal |

|

|

14 |

CLK- |

Encoder specific signal |

|

|

15 |

GND |

Reference for the supply |

|

|

16 |

5P |

Supply VDC |

|

|

E |

- |

- |

|

|

Shield |

Plug housing |

|

Connection:

|

Mating plug |

Encoder plug M23, female, 17-poles |

|

Recommended cable cross section |

shielded 4 x (2 x 0.25 mm2) twisted-pair + (4 x 0.5 mm2) + (2 x 0.75 mm2) |

|

Shield connection |

Apply on both sides |