iC: [X08 / X09] 24 VDC supply voltage - Transmission

|

NOTE |

|

|---|---|

| Material damage! |

Material damage due to overvoltage! An overvoltage at the connections X08 and X09 (24 VDC) is not monitored and damages the device Steps to prevent:

|

Description:

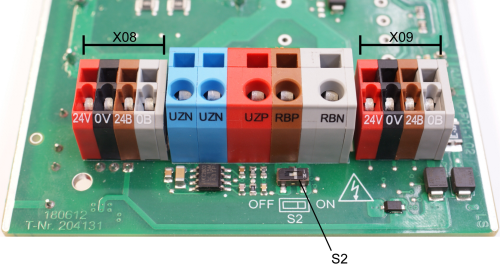

X08: 24 VDC supply voltage supply line for electronics and STO / motor holding brake

X09: 24 VDC supply voltage transmission for electronics and STO / motor holding brake

External power supply units that provides the 24 VDC supply voltage for connections 24V and they must have a "safe isolation" (PELV) according to EN 61800-5-1. The 0 V potential must be connected with PE. The current of the 24V and supply must be limited to

A power supply unit is integrated into the that supplies the 24 VDC from the DC bus for the electronics supply. The power supply unit is active when the SMD-DIP switch S2 is in the "ON" switch setting (delivery status for devices with an integrated power supply unit).

|

|

Significant prerequisite for certification of a machine with functional safety: When using the functional safety the internal power supply unit must be deactivated (S2 = OFF), and the 24 VDC (for connections 24V and ) is provided externally with a PELV power supply, otherwise the conditions for the use of functional safety are not satisfied! |

In the event of a failure of the 24 VDC supply to the electronics > 10 ms, the system ready message is internally reset.

|

Switch off the internal 24 VDC supply voltage from the DC bus with the switch S2

|

|||||

|

|||||

|

The S2 switch is located in the |

|||||

Wiring for STO safety function according to EN 61800-5-2

|

|

Switch off the internal 24 VDC supply voltage from the DC bus with the switch S2 |

According to EN 61800-5-2 the error 'Short circuit between two conductors' will be excluded in the following cases:

- For permanently connected conductors which are protected from external damage (e.g. cable channel)

- Different sheathed cables (e.g. separate cables at iC for 24B / 0B and 24V / 0V)

- Inside an electrical installation space

- The conductors are separately screened and have a earth connection

Technical data

24 VDC supply voltage:

- 24 VDC ± 15% PELV power supply acc. to IEC/EN 60950

- Ripple max. 5%, with integrated switch-on current limitation

- The 0 V potential of the power supply unit should be earthed at the central PE

Design

|

Type |

Pole |

Sort |

Manufacturer |

Designation |

|---|---|---|---|---|

|

Terminal with tension spring connection |

4 |

|

WAGO |

739 |

Actuating tool: Screwdriver with a blade 2.5 x 0.4 mm

The cable is attached to the housing: Cable gland M25 x 1.5

Assignment

|

[X08] |

Signal |

Description |

|||||

|---|---|---|---|---|---|---|---|

|

24V 1) |

24 VDC supply voltage |

||||||

|

0V |

Reference potential for 24 VDC |

||||||

|

24B 1) |

Supply voltage 24 VDC

The supply voltage directly controls the STO state and at the same time supplies an optional motor holding brake with power. |

||||||

|

0B |

Reference potential for 24B / transmission |

|

1) |

The current of the 24V |

|

[X09] |

Signal |

Description |

|---|---|---|

|

24V 1) |

24 VDC transmission |

|

|

0V |

Reference potential for 24 VDC |

|

|

24B 1) |

24 VDC transmission |

|

|

0B |

Reference potential for 24B |

|

1) |

Please refer to the device description of the connected device for the pin assignment |

Connection

|

Cable |

4 x 0.5 mm2 / AWG 20, shielded |

|

Max. conductor cross-section of the terminal |

Flexible cable with a wire end sleeve with plastic collar: 1 mm2 |

|

Stripping length |

5 - 6 mm |

|

Shield connection |

Apply on both sides |