Safely-limited speed (SLS)

Properties

- Safety function according to DIN EN 61800-5-2:2008-04

- Parameterisable safe speed range (2-channel actual speed value monitoring)

- Parameterised speed limit automatically is positive and negative speed limit value

- 2 individually configurable functions SLS1 and SLS2

- Parameterisable stop function in case of error

Description

The safety function is started by the corresponding bit in the control data.

The acknowledgement is fed back by status data.

The started SLS safety function monitors the deceleration procedure of the drive, and subsequently the operation within a parameterised safe speed range. The speed change must be initiated by the user controller.

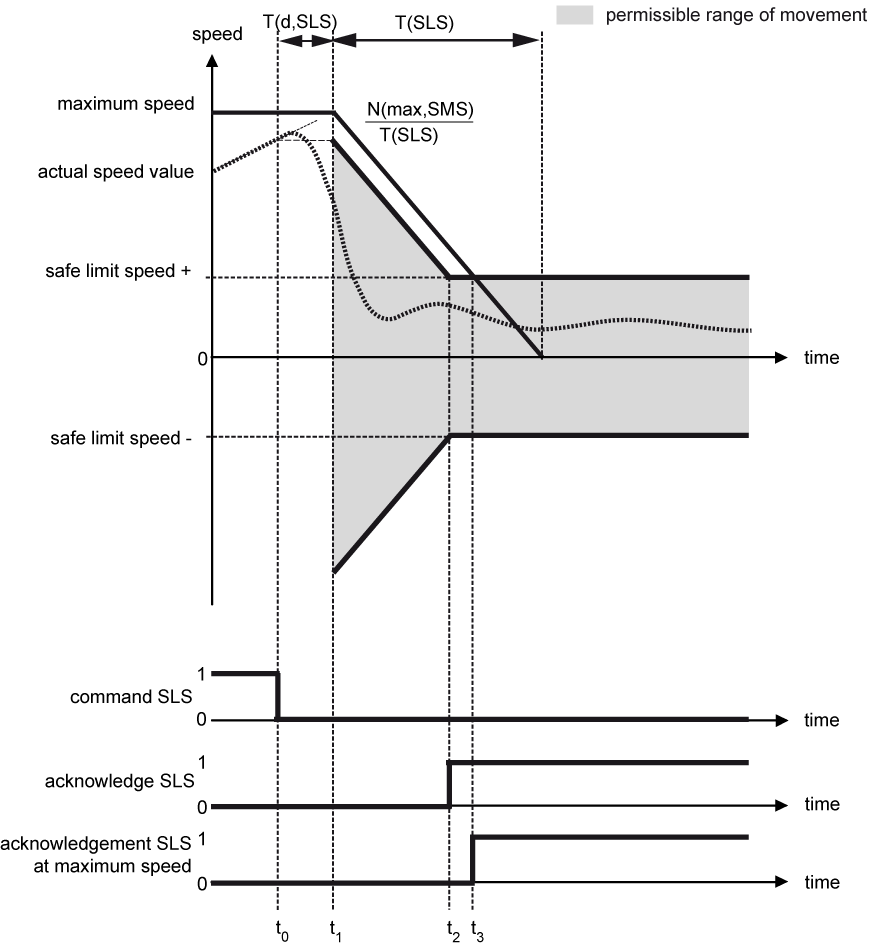

Example 1: Drive movement in the permissible range of movement

|

Time t |

Explanation |

|---|---|

|

t = t0

|

The safety function is started. |

|

t0 < t < t1 |

During the transition period, the actual speed value of the drive must be adjusted to the parameterised limits of the started safety function. The parameterised limits are not monitored yet. |

|

t1 ≤ t < t2 |

The safety function monitors the parameterised ramp and checks whether the actual speed value meets the permissible range of movement. |

|

t ≥ t2 |

The safety function switches the drive into the SLS state and sets the SLS acknowledgement bit. In the SLS state, the safety function monitors whether the actual speed value meets the parameterised safe speed range. |

|

t = t3 |

Acknowledgement SLS at maximum speed |

Reaction in case of an error

As soon as the safety function detects a deviation from the limits of the controlled values, the drive executes a safe stop function that has previously been set by parameter ('Safe torque off (STO)', 'Safe stop 1 (SS1)' or 'Safe stop 2 (SS2)') (example 2).

The 2 SLS safety functions monitor the drive independently from each other. As soon as the drive leaves the parameterised speed range in a safety function, the stop function becomes active that has been parameterised for this SLS (example 3).

|

|

|

|

|

Danger to life due to unexpected movements! The drive will be torque-free in the status 'Safe torque off (STO)', in case of mains failure or in case of faulty drive controller. External application of force on the drive axis may result in life-threatening movements (e.g. hanging axes can fall down). Steps to prevent:

|

|

|

|

|

|

Danger due to unexpected stop function! If there are different error reactions projected for the safety functions, an unexpected final state can occur in case of error. Example: Steps to prevent:

|

|

|

The reaction time of the drive in case of error is prolonged by the reaction time of the parameterised stop function! |

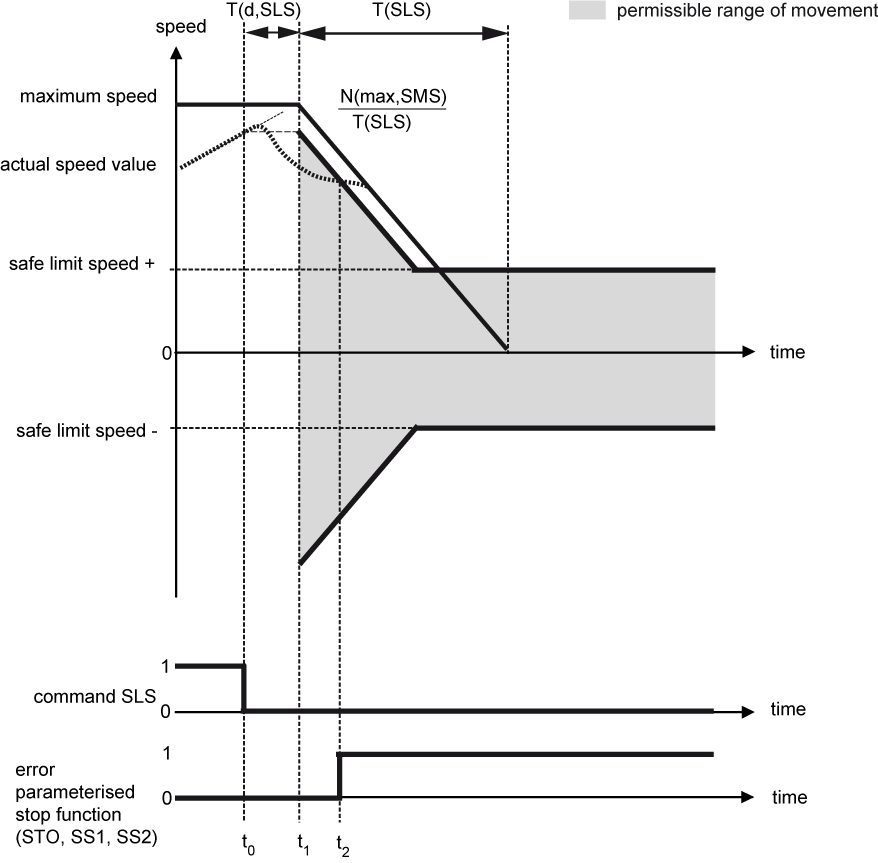

Example 2: Drive movement deviates from the permissible range of movement

|

Time t |

Explanation |

|---|---|

|

t = t0

|

The safety function is started. |

|

t0 < t < t1 |

During the transition period, the actual speed value of the drive must be adjusted to the parameterised limits of the started safety function. The parameterised limits are not monitored yet. |

|

t1 ≤ t < t2 |

The safety function monitors the parameterised ramp and checks whether the actual speed value meets the permissible range of movement. |

|

t = t2 |

The safety function detects an error, starts the parameterised stop function and sets the error bit. |

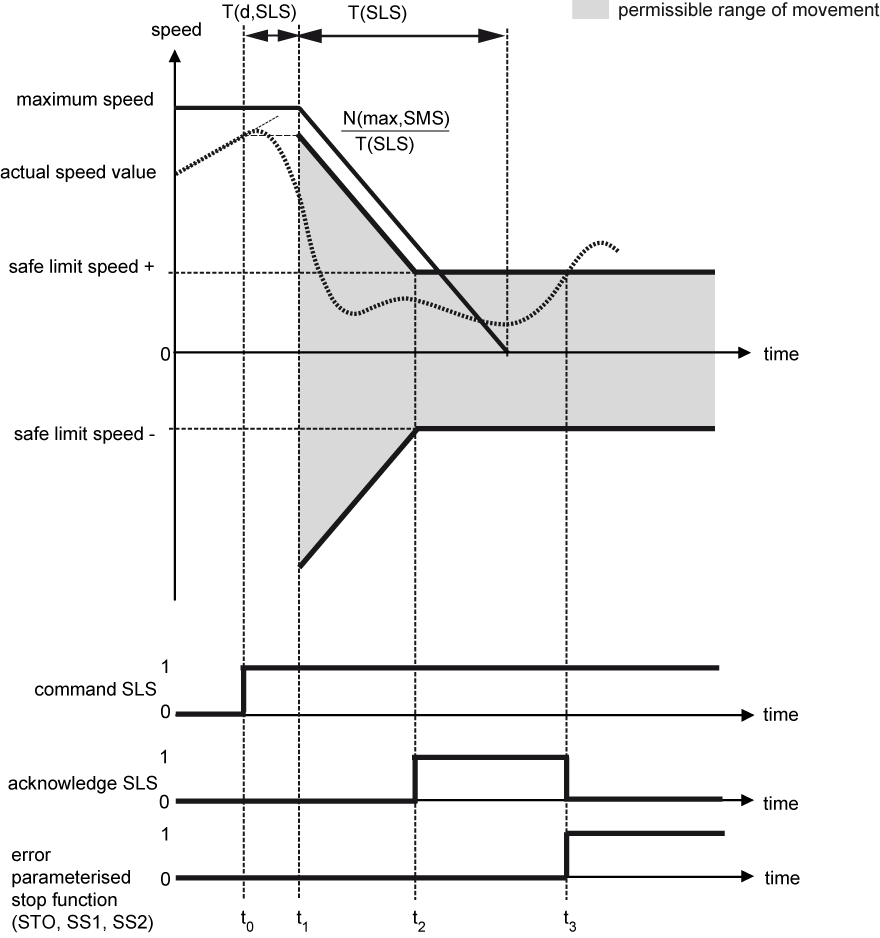

Example 3: Deviation from the speed range in the SLS state

|

Time t |

Explanation |

|---|---|

|

t = t0 |

The safety function is started. |

|

t0 < t < t1 |

During the transition period, the actual speed value of the drive must be adjusted to the parameterised limits of the started safety function. The parameterised limits are not monitored yet. |

|

t1 ≤ t < t2 |

The safety function monitors the parameterised ramp and checks whether the actual speed value meets the permissible range of movement. |

|

t = t2 |

The safety function switches the drive into the SLS state and sets the SLS acknowledgement bit. |

|

t2 ≤ t < t3 |

In the SLS state, the safety function monitors whether the actual speed value meets the parameterised safe speed range. |

|

t = t3 |

The safety function detects an error, starts the parameterised stop function and sets the error bit. The SLS acknowledgement is reset. |

Acknowledge an error with "Clear error"

As soon as an active safety function detects a deviation from the limits of the monitored values, the drive is set to the intended stop function. The error bit (FSoE status bit 7) is set and the acknowledgment of the safe status is withdrawn.

With the 'Clear error' signal (FSoE control bit 7 or the 'Clear error' command in the drive controller) the

error status ist acknowledged (deleted). If during and after the 'Clear error' the start signal from a previous safety function is still active and no other changes to the settings of the safety function have been made, the safety function restarts and also transition times (if available) work again.

Parameters

Safe parameters

|

Parameter |

Name |

Code |

Unit |

Min |

Max |

|

'SLS1 transition period' |

T(d,SLS1) |

ms |

0 |

65535 |

|

'SLS1 brake ramp time' |

T(SLS1) |

ms |

0 |

65535 |

|

'SLS1 safe limit speed' |

N(limit,SLS1) |

rpm |

-60000 |

60000 |

|

'SLS1 error reaction' |

SLS1_ERR |

- |

0 |

2 |

|

'SLS2 transition period' |

T(d,SLS2) |

ms |

0 |

65535 |

|

'SLS2 brake ramp time' |

T(SLS2) |

ms |

0 |

65535 |

|

'SLS2 safe limit speed' |

N(limit,SLS2) |

rpm |

-60000 |

60000 |

|

'SLS2 error reaction' |

SLS2_ERR |

- |

0 |

2 |

|

'SMS safe maximum speed' |

N(max,SMS) |

rpm |

0 |

60000 |