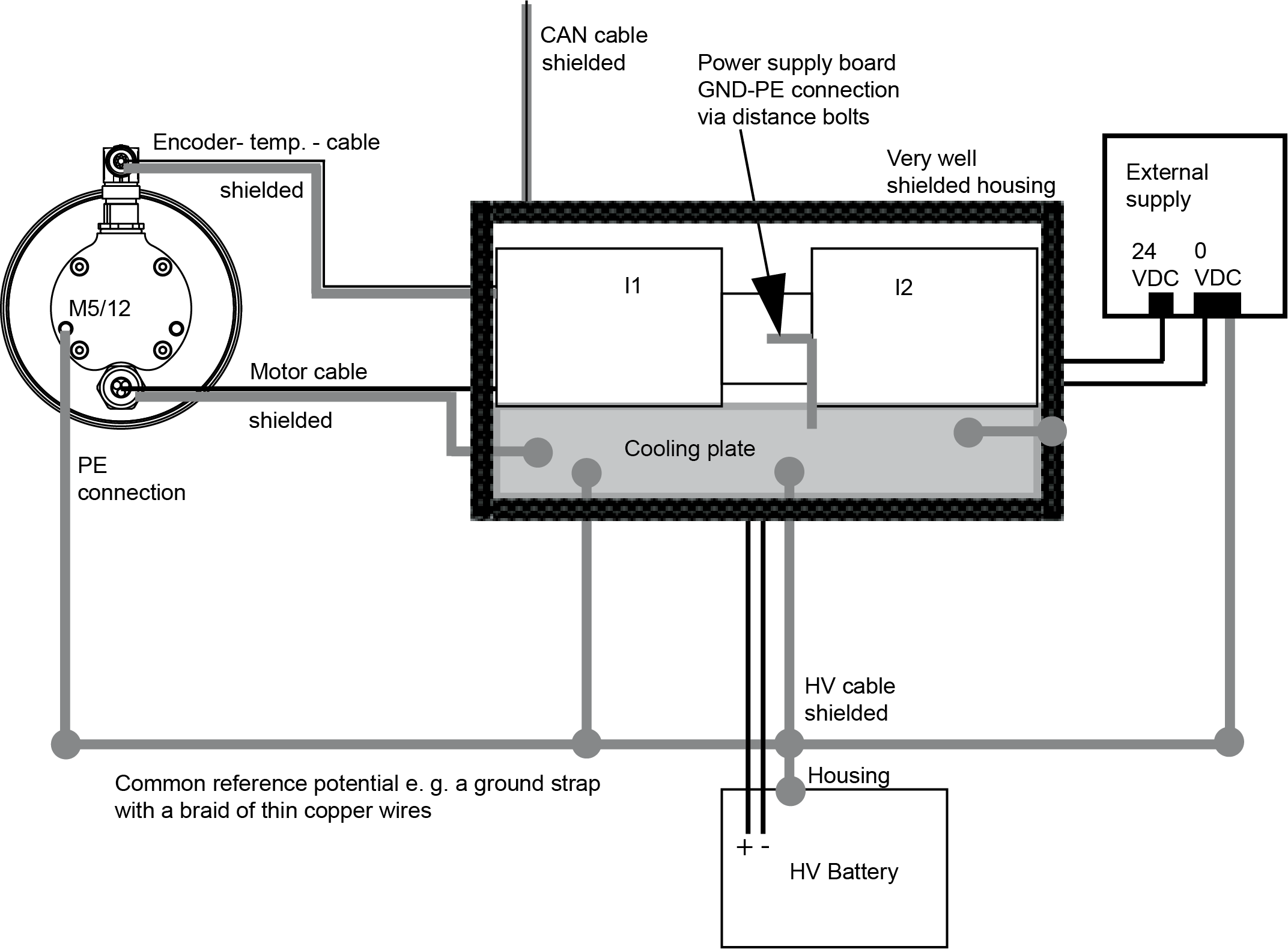

PE ground connection – overview

A highly conductive connection must be implemented in the vehicle to provide the ground connection. This is used as a 0 VDC ground for all signal and operating voltages. For vehicles without a metal frame, a ground strap made from a braiding of fine copper wires can be used.

Motor cable

The motor cable must be a shielded cable with tinned copper braiding. The motor cable shield must be connected to the shield for the unconnected cable end of the motor across the surface. Use non-adhesive heat-shrink tubing for this. Press the two pieces of shielding firmly together.

At the inverter, the shield must be placed across the surface of the cold plate. Ensure good contact with the cold plate.

|

|

The motor cable shield can prevent interference to a large extent. (Large diameter → skin effect) |

HV cable

When greater than 1 m, the HV cable must have a copper shield.

The end of the shield must be connected to the designated casing ground on the cold plate and on the battery side.

|

|

The end of the shield must NOT be connected to the negative terminal (-) of the HV battery. |

Encoder temp. cable

The encoder cable shield must be grounded on both sides.

Via the circular connector casing on the motor and via the metalized D-SUB casing on the inverter (connection X131).

Power supply board

The power supply board GND is connected to the cold plate via the standoffs.

Cold plate

The cold plate must be connected to the common vehicle ground.

External power supply

The 0 VDC connection must be connected to the common vehicle ground.