P- / Q-encoder

The following data are typical guidelines and can therefore deviate for the specific motor.

|

Encoder type |

Technical description |

Manufacturer / |

|---|

| P |

|

Heidenhain ECI 1118 ECI 1319 ECI 119 |

|

Resolution: 18 / 19 bit/revolution 2) |

||

|

Measuring principle: inductive, permanent magnets ( ) |

||

| Protocol: EnDat 2.2 light | ||

| Q |

|

Heidenhain EQI 1130 EQI 1331 |

|

Resolution: 18 / 19 bit/revolution 2) |

||

|

Measuring principle: inductive ( ) |

||

|

Protocol: EnDat 2.2 light |

||

| 2) | depends on motor size |

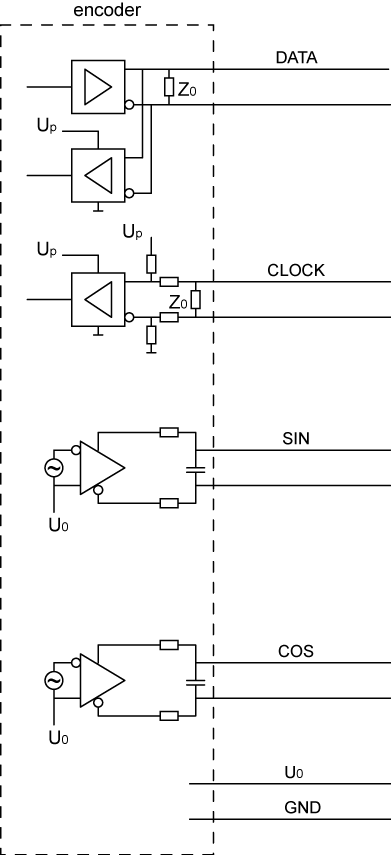

Output signal EnDat 2.2 light

The EnDat protocol transfers digital data between an encoder and the evaluation electronics according to the RS485 specification. The absolute positions are transferred synchronously to the cycle signal (CLOCK ) specified by the evaluation electronics.

EnDat 2.2 has an expanded command set compared to EnDat 2.1. The command set of EnDat 2.1 is a component of EnDat 2.2.

|

|

EnDat 2.2 light means, that the encoder supports EnDat 2.2, which is used only with the commands of EnDat 2.1 from the AMK controller. |

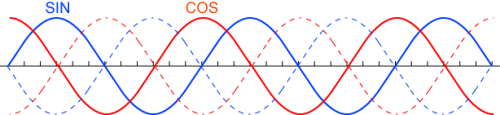

Output signal (SIN/COS track)

Signal sequence depicted for clockwise turning of the motor shaft with direction of view toward the A bearing side of the shaft.

|

2,5 V |

|

| Data |

P-encoder |

Q-encoder |

||||

|---|---|---|---|---|---|---|

|

ECI 1118 |

ECI 1319 |

ECI 119 |

EQI 1130 |

EQI 1331 |

||

| Voltage supply |

VDC |

5 ±5 % |

4.75 - 10 |

5 ±5 % |

5 ±5 % |

4.75 - 10 |

| Current consumption without load (5 V) |

mA |

120 |

80 |

135 |

145 |

90 |

| Mechanically permitted speed |

1/min |

15000 |

15000 |

6000 |

12000 |

12000 |

|

Analog signals (SIN/COS) |

||||||

| Analog resolution |

Per./rotation |

16 |

32 |

32 |

16 |

32 |

| Signal level |

VSS |

1 ±0.2 |

1 ±0.2 |

|||

|

Offset |

V |

2.5 ±0.5 |

2.5 ±0.5 |

|||

|

Absolute position values |

||||||

|

Signal characteristic |

|

RS485 |

RS485 |

|||

| Digital resolution |

Pos./rotation |

262144 |

524288 |

524288 |

262144 |

524288 |

| Rotations |

|

1 |

4096 (12 Bit) |

|||

Output circuit

Z0 = 120 Ω